Overall solutions

Intelligent automation solutions for industry

Economical. Flexible. Efficient.

Your advantages:- Highest flexibility

- Safe operation according to ISO 10218-2

- Highest efficiency

- Lowest project costs

- High reliability & cost transparency

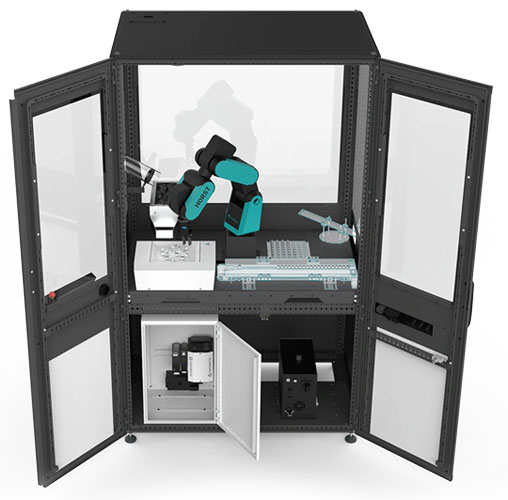

Solution Kit Pick and Place

With intuitive operation and user-friendly software, this complete solution is ready for you to use right away. Take advantage of the benefits of automation without any further effort!

The worry-free, easy way to automate:- Seamless integration

- Conveniently CE-compliant

- Cutting-edge technology and AI

- Flexible and adaptable

- Smart connectivity and digital services

- Return on investment within 6 months

Solution Kit Part Separation

Solution Kit Part Separation

The tailor-made complete solution helps you to master your specific challenges in part separation.

- Fast project planning and implementation

- Profitable in as little as six months

- Flexible integration

- Extra customization and add-ons

- CE-compliant and energy-efficient

Solution Kit Machine Tending

With our preconfigured Solution Kit Machine Tending, you achieve the shortest installation and changeover times as well as the highest adaptability of your application.

- Low project costs, extremely fast setup

- Full flexibility, easy task switching

- No effort on your part for risk assessment

- Additional services make project launch even easier

- Short machine downtime for higher throughput

Mobile Robot Base

Thanks to the Mobile Robot Base from fruitcore robotics, the industrial robot HORST is multi-functional and therefore particularly flexible in terms of application. The platform can simply be moved manually to its site of operation. This makes it an ideal and sensible addition for the automated production of even small series.

Equipment:

- Emergency stop button

- Mount for robot control panel

- Internal switch cabinet attachment including ducts to HORST

- Lockable switch cabinet door with a key to the switch cabinet on the front

- Aluminum baseplate including hole pattern for HORST (can be positioned at the center or side) and M8 hole pattern for various applications (grid dimension of 100 x 100 mm; other hole patterns available upon request)

Optional:

- Integrated 2D laser scanners for up to 360° monitoring of the hazard area

- Lateral safety guards

- Machine flange for latching onto machines with repeatability

- Individual adaptations upon request

| Technical data | Mobile Robot Base | |||

|---|---|---|---|---|

| Dimensions in mm (L x W x H) | 1000 x 600 x 900 | 1200 x 800 x 900 | 1500 x 1000 x 900 | |

| Empty weight in kg | 110 | 130 | 160 | |

| Payload in kg | 300 | 300 | 300 | |

| Carriage | 4 rubberized caster wheels, Floor lock | |||